Tag: portable steam engine

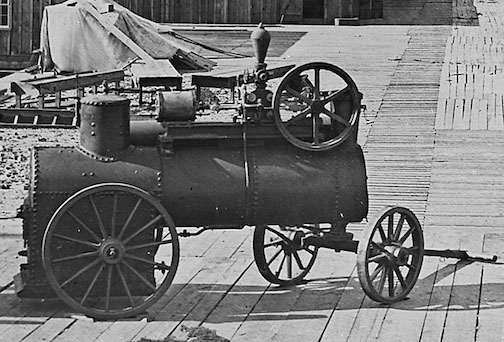

Wikipedia says: A portable engine is an engine, either a steam engine or an internal combustion engine, that sits in one place while operating (providing power to machinery), but (unlike a stationary engine) is portable and thus can be easily moved from one work site to another. Mounted on wheels or skids, it is either towed to the work site or moves there via self-propulsion.

Wikipedia says: A portable engine is an engine, either a steam engine or an internal combustion engine, that sits in one place while operating (providing power to machinery), but (unlike a stationary engine) is portable and thus can be easily moved from one work site to another. Mounted on wheels or skids, it is either towed to the work site or moves there via self-propulsion.

Portable engines were in common use in industrialised countries from the early 19th through early 20th centuries, during an era when mechanical power transmission was widespread.

Portable engines during their heyday were typically towed to their work sites by draft horses or oxen, or, in the latter part of that era, motive power including self-propulsion or towing by traction engines, steam tractors, other tractors, or trucks. They were used to drive agricultural machinery (such as threshing machines), milling machinery (such as gristmills, sawmills, and ore mills), pumps and fans (such as in mines and oil wells), and factory line shafts (for machine tools, power hammers, presses, and other machines).

In common with many other areas of steam technology, the initial design and development of portable engines took place in England, with many other countries initially importing British-built equipment rather than developing their own.

Early steam engines were too large and expensive for use on the average farm; however, the first positive evidence of steam power being used to drive a threshing machine was in 1799 in north Yorkshire. The next recorded application was in 1812, when Richard Trevithick designed the first ‘semi-portable’ stationary steam engine for agricultural use, known as a “barn engine”. This was a high-pressure, rotative engine with a Cornish boiler, for Sir Christopher Hawkins of Probus, Cornwall. It was used to drive a corn threshing machine and was much cheaper to run than the horses it replaced. Indeed, it was so successful that it remained in use for nearly 70 years, and has been preserved by the Science Museum in London. Although termed ‘semi-portable’, as they could be transported and installed without being dismantled, these engines were essentially stationary. They were used to drive such barn machinery as pumps and hammer mills, bone-crushers, chaff and turnip cutters, and fixed and mobile threshing drums.

It was not until about 1839 that the truly portable engine appeared, allowing the application of steam power beyond the confines of the farmyard. William Tuxford of Boston, Lincolnshire started manufacture of an engine built around a locomotive-style boiler with horizontal smoke tubes. A single cylinder and the crankshaft were mounted on top of the boiler, and the whole assembly was mounted on four wheels: the front pair being steerable and fitted with shafts for horse-haulage between jobs. A large flywheel was mounted on the crankshaft, and a stout leather belt was used to transfer the drive to the equipment being driven.

Ransomes built an early portable in 1841 and exhibited it at the Royal Agricultural Society show that year. The next year Ransomes converted the steam engine to self driving, thus making an intermediate step towards the traction engine.

Several Tuxford engines were displayed at the Royal Agricultural Society’s Show at Bristol in 1842, and other manufacturers soon joined in, using the basic design of the Tuxford engine as a pattern for the majority of portable engines produced thereafter.

Early manufacturers in the UK included:

Alexander Dean of Birmingham

Ransomes of Ipswich

William Tuxford and Sons of Boston, Lincolnshire

Howden of Boston, Lincolnshire

Clayton & Shuttleworth of Lincoln

This last manufacturer is particularly noteworthy here. The first Clayton & Shuttleworth portable was built in 1845, a two-cylinder engine. In 1852, the company won a gold medal for a portable engine at the Royal Agricultural Society’s Gloucester show, and thereafter the business expanded rapidly: they established a second works, in Vienna in 1857, to target the European market, and by 1890 the company had manufactured over 26,000 portable engines, many being exported all over the world.

In the 1850s, John Fowler used a Clayton & Shuttleworth portable engine to drive apparatus in the first public demonstrations of the application of cable haulage to cultivation.

In parallel with the early portable engine development, many engineers attempted to make them self-propelled – the fore-runners of the traction engine. In most cases this was achieved by fitting a sprocket on the end of the crankshaft, and running a chain from this to a larger sprocket on the rear axle. These experiments met with mixed success.

As noted early on by Thomas Aveling (later of Aveling & Porter fame), it was absurd to use four horses to pull a steam engine from job-to-job, when the engine possessed ten times the strength of the horses. It was therefore inevitable, once self-propelled traction engines had become sufficiently reliable, that they would take over the roles of many portable engines, and this indeed started to happen from the late 1860s.

Other builders manufactured engines around the world. Small machine shops could assemble units with a small engine and vertical boiler and put it on wheels. In North America dozens of builders entered the market—Case, Sawyer Massey, and Gaar Scott for example. Native builders erected engines in France, Italy, Sweden and Germany.

However, the portable engine was never completely replaced by the traction engine. Firstly, the portable, having no gearing, was markedly cheaper, and secondly, numerous applications benefitted from a simple steam engine that could be moved, but did not require the additional complexity of one that could move itself.